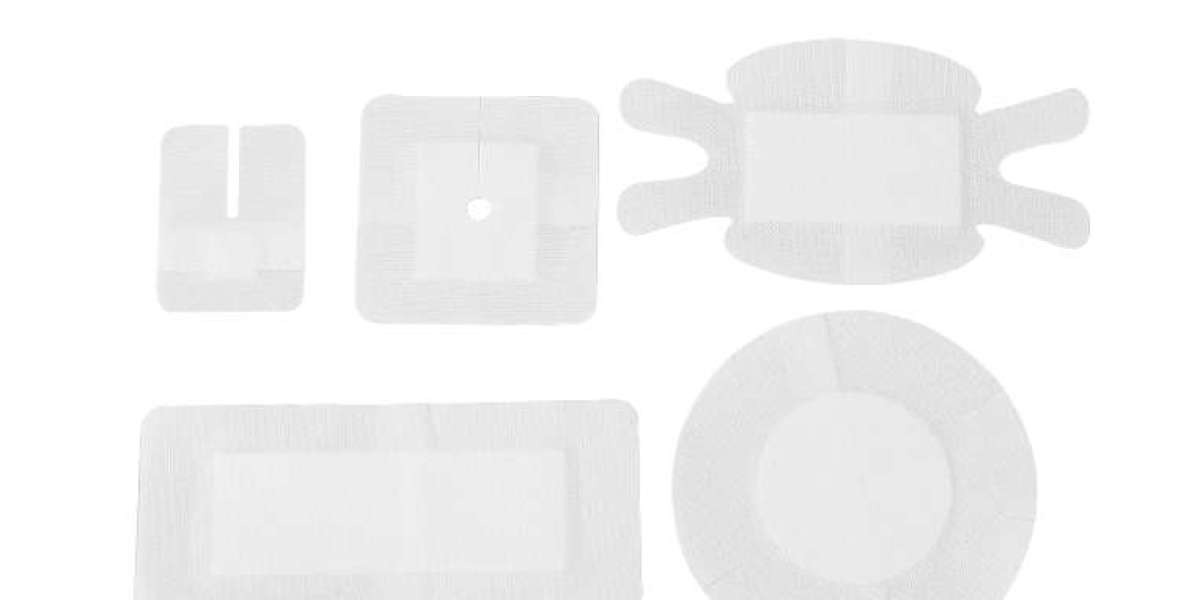

The sterile wound dressing market has been evolving steadily, reflecting new trends in material development, packaging, and user convenience. Manufacturers are focusing on innovative materials such as non-woven fabrics and lightweight foams that maintain structure and comfort. Adhesive borders and layered pads are designed to fit various body contours while minimizing material waste.

From a production standpoint, maintaining packaging integrity and sterility until use is a key priority. Factories optimize processes to control costs and ensure consistent quality. The demand for dressings that are easy to apply in home or care settings has increased, influencing both design and packaging decisions. Product developers now consider user handling, flexibility, and storage conditions to make dressings more convenient for different scenarios.

Users often raise practical questions about selecting the right size and material for daily use or for specific needs. Attention to packaging, storage, and timely replacement helps maintain usability. Some dressings include adhesive strips that make positioning easier while keeping the pad secure during movement. Understanding these points helps users apply dressings efficiently without unnecessary waste.

In conclusion, the sterile wound dressing has become a design-conscious and user-oriented product. Careful attention to material selection, packaging, and handling guidelines ensures that it serves its intended purpose efficiently in a variety of personal and professional settings.