Plastic container mould technology serves as the fundamental manufacturing process behind countless packaging products used in daily life. This specialized tooling system transforms raw polymer materials into finished containers through precise engineering and controlled production processes. The design and construction of a plastic container mould require sophisticated expertise in materials science, mechanical engineering, and production technology. These mould systems determine the final container's shape, structural integrity, and functional characteristics, making them essential components in manufacturing operations across various industries. The continuous development of plastic container mould technology enables production of increasingly sophisticated packaging solutions that meet evolving market demands.

The engineering design phase for a plastic container mould involves comprehensive planning to ensure successful manufacturing outcomes. Designers must consider factors such as material flow, cooling efficiency, and ejection mechanisms when developing a plastic container mould. Advanced software tools facilitate the creation of detailed mould designs that account for all functional requirements and production parameters. The planning process for a plastic container mould typically includes prototyping and testing phases to verify performance before full-scale production begins. This careful approach to plastic container mould development helps prevent issues during manufacturing and ensures consistent product quality.

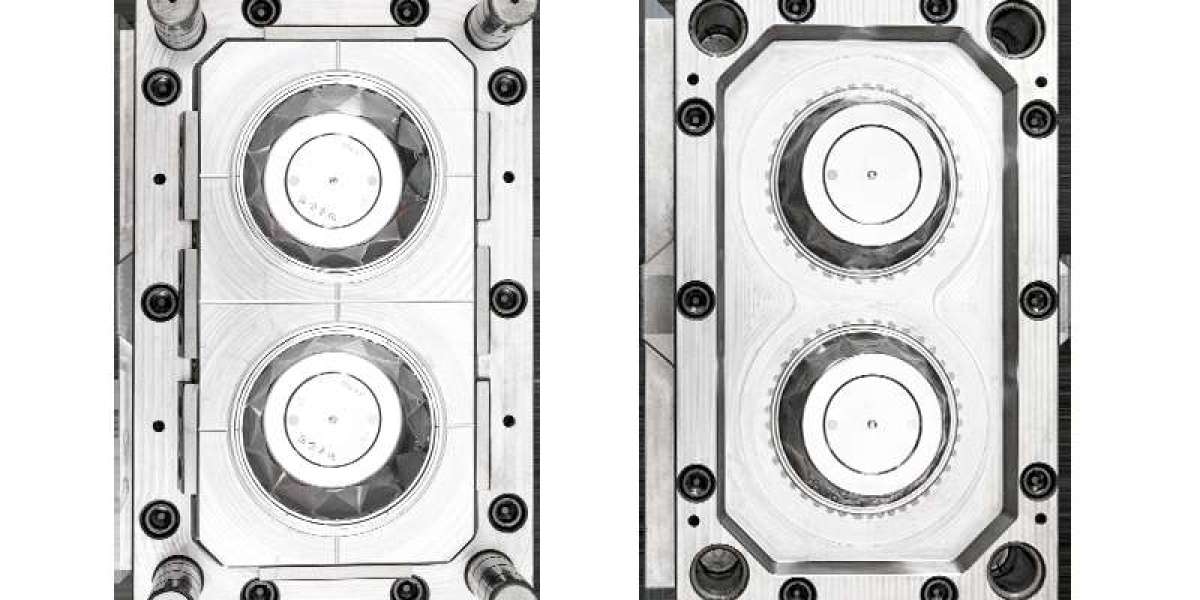

Manufacturing processes for creating a plastic container mould require precision machining capabilities and specialized technical knowledge. Computer Numerical Control (CNC) equipment typically machines mould components from hardened steel or aluminum blocks to exact specifications. The cavity and core sections of a plastic container mould must be meticulously finished and polished to achieve the desired surface quality on finished products. Electrical discharge machining (EDM) processes create intricate details and complex geometries within the plastic container mould structure. These manufacturing techniques ensure that each plastic container mould meets precise dimensional tolerances and functional requirements.

Material selection represents a critical consideration in plastic container mould construction that directly affects performance and longevity. hardened tool steels provide durability for high-volume production runs using a plastic container mould. Aluminum alloys offer faster heat transfer and are suitable for shorter production cycles. Surface treatments applied to a plastic container mould can enhance wear resistance and prevent material sticking. The choice of materials for a plastic container mould depends on production volume, polymer type, and economic factors specific to each manufacturing application.

Plastic container mould technology represents a sophisticated manufacturing discipline that enables mass production of packaging solutions. The precision engineering and careful construction of these mould systems support efficient manufacturing processes across numerous industries. Continuous advancements in plastic container mould design and manufacturing techniques contribute to improved production efficiency and product quality. This specialized field demonstrates how thoughtful engineering and precise manufacturing can create tools that transform raw materials into functional products that serve essential needs in commerce and daily life.